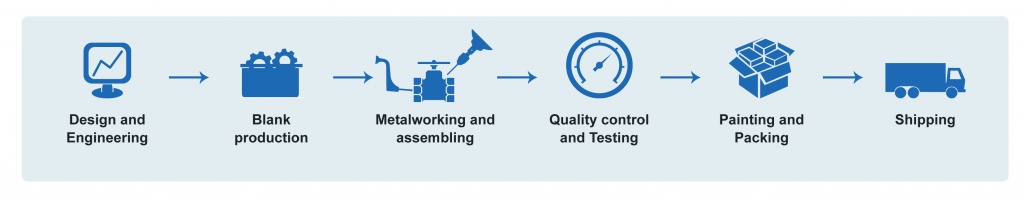

The production process goes through all the technological stages from design and engineering, to assembly and testing of the finished products.

1. DESIGN

We constantly work on advancement of existing constructions and develop new products for demanding working conditions and special types of medium. New equipment design and material selection are carried in accordance with customers’ requirements.

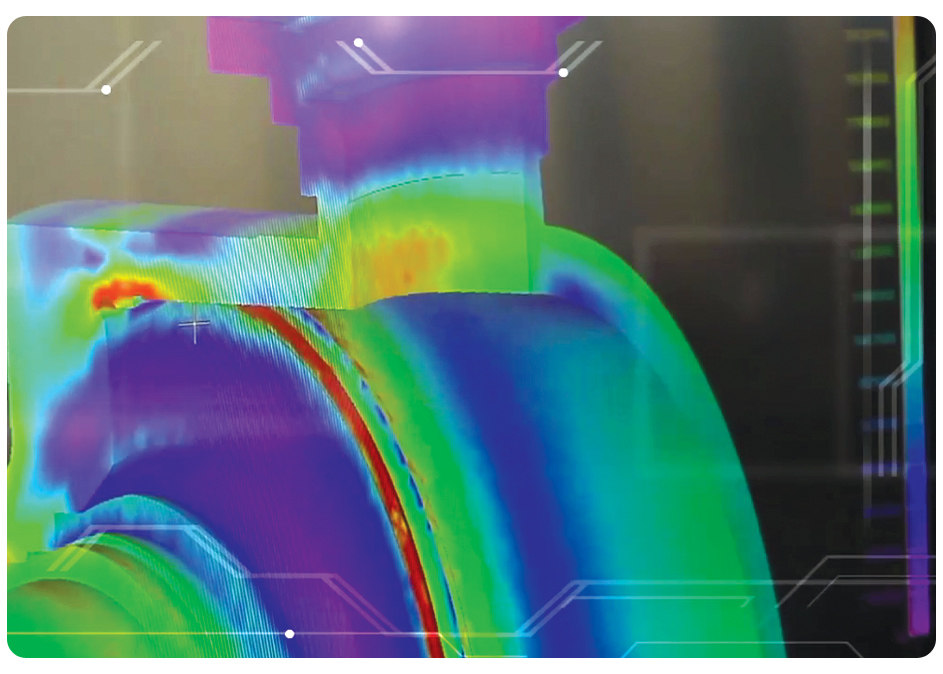

DESIGN ENGINEERING & ENGINEERING ANALYSIS

- Tridimensional aided design

- Quality control with the use of finite-element method

- Analysis of hydrogasodynamic features

- Strength and functional test under seismic and other loads

- Pig valves

- Shut-off control ball valves

- Axial flow check valves

- Electrohydraulic actuators

2. PRODUCTION

- NC machines; multifunction machining centers

- Automated welding system; cutting, overlaying, bandsawing machines

- Shot-blasting chambers and automated painting line

- Personnel qualification in accordance with EU requirements

3. INSPECTION

INCOMING MATERIAL INSPECTION

- metallography

- hemical analysis

- mechanical analysis

IN-PROCESS INSPECTION

- dye-penetrant inspection

- ultrasonic and X-ray tests

- acoustic emission diagnostics

- vacuum tightness tests

- magnetic particle test

PRODUCT TESTING

- acceptance tests are held in the presence of Customer’s representatives

- design type tests

- sampling tests for the compliance with the requirements of standards and technical specifications